Product Spotlight March 2024

With the rapid growth of the Electric Vehicle market, the demand of EV chargers has been increasing tremendously in these years. Based on types of electrical currents for charging, EV chargers are divided into AC chargers and DC chargers. Featured by compact size and easy installation, AC charger is generally most appropriate for residential units, workplaces and communities, to be installed in public parking lot/garages. With its high market demand, AC chargers currently are the mainstream in the market.

Generally, EV charging currents range from a few kilowatts to tens of kilowatts, highlighting the critical importance of safety protection in EV charging systems. Several countries have introduced rigorous safety regulations, emphasizing the necessity of leakage protection for EV chargers.

In electric vehicle charging, a large number of AC-DC conversion (rectifier/inverter) circuits exist. If a leakage fault occurs, there will be not only Type AC and pulsating direct residual current, but also DC residual current and smooth DC residual current generated by two-phase/three-phase rectification and filtering. Therefore, the leakage protection solution must be capable of detecting both AC and DC residual currents.

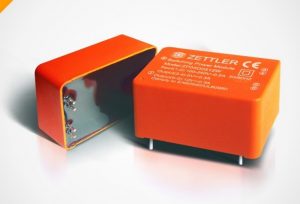

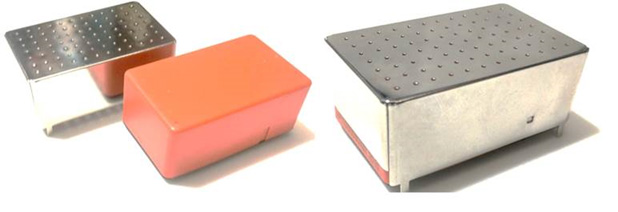

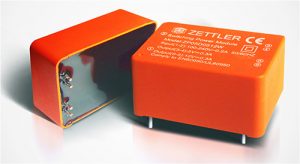

ZETTLER Magnetics has recently developed a series of EV-RCD module with leakage protection solution, which are suitable for Mode 2 and Mode 3 EV chargers under European standards.

Leakage detect Mechanism

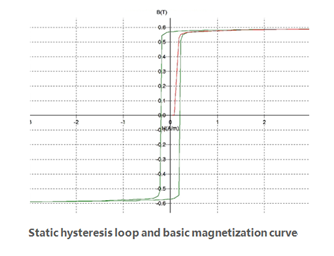

The ZETTLER EV-RCD module adopts the principle of detecting differential current by the response of specific Amorphous cores to tiny magnetic field changes. When an electrical system is working perfectly, the vectorial sum of the currents on all current-carrying conductors of a supply line is equal to zero, and thus there is no magnetic field around the supply line.

If a residual current does occur and is drained outside of the supply line via an object or the ground due to an insulation fault, a differential current greater than zero will exist.

The ZETTLER EV-RCD modules use an Amorphous core with a high remanence ratio and integrates a self-excitation oscillation circuit to generate periodic oscillation. When the differential current passes through the core, the magnetic field would change, resulting in the variation on the oscillation waveform accordingly.

The ZETTLER modules will determine the differential current value and the type through the comparison of waveform variation and feedback AC and DC leakage signal correspondingly when the value exceeds the limitation of safety standard.

Compared with the traditional type A leakage protection products, the ZETTLER EV-RCD module has the following advantages:

- Excellent accuracy: Detect 3-6 mA DC differential current, and send response signal according to safety requirements.

- High surge-current withstand capacity: Withstand 3.000 Ainstantaneous current surge without damage.

- The ability to detect various current types: Fulfill type B leakage detecting.

List of EV-RCD Modules

| Model No. | Rated Input Voltage | Rated Input Current | DC: | AC: | Digital I/O | Operating Temp. Range | Conforms to Safety Standard | Connection Type: | |

|---|---|---|---|---|---|---|---|---|---|

| Single-phase | Three-phrase | 3-6mA | 15-30mA | ||||||

| APR00T0332WX-003 | 440V | 32A | 32A | Action | NC | 5V/30mA | -40-85℃ | IEC62955 | PIN |

| APE00T0332WX-001 | 440V | 32A | 32A | Action | Action | 5V/30mA | -40-85℃ | IEC62752 | PIN |

| APR00D0163WX-001 | 440V | 63A | 32A | Action | NC | 5V/30mA | -40-85℃ | IEC62955 | Hole |

| APE00D0163WX-001 | 440V | 63A | 32A | Action | Action | 5V/30mA | -40-85℃ | IEC62752 | Hole |

| APR00T0332WT-001 | 440V | 32A | 32A | Action | NC | 5V/30mA | -40-85℃ | IEC62955 | PIN |

| APE00T0332WT-001 | 440V | 32A | 32A | Action | Action | 5V/30mA | -40-85℃ | IEC62752 | PIN |

| APR00D0163WT-001 | 440V | 63A | 32A | Action | NC | 5V/30mA | -40-85℃ | IEC62955 | Hole |

| APE00D0163WT-001 | 440V | 63A | 32A | Action | Action | 5V/30mA | -40-85℃ | IEC62752 | Hole |

| APR00D0132WG-001 | 440V | 32A | 32A | Action | NC | 5V/30mA | -40-85℃ | IEC62955 | Hole |

| APE00D0332WG-010 | 440V | 32A | 32A | Action | Action | 5V/30mA | -40-85℃ | IEC62752 | Hole |

| APE00D0332WG-110 | 440V | 32A | 32A | Action | Action | 12V/30mA | -40-85℃ | IEC62752 | Hole |

| APR00D0332WG-001 | 440V | 32A | 32A | Action | NC | 5V/30mA | -40-85℃ | IEC62955 | Hole |

| APE00D0332WG-014 | 440V | 32A | 32A | Action | Action | 5V/30mA | -40-85℃ | IEC62752 | Hole |

| APE00D0332WG-114 | 440V | 32A | 32A | Action | Action | 12V/30mA | -40-85℃ | IEC62752 | Hole |

Currently, drilling, fastening and screwdriving tools hold the largest market share in the power tools market, and a similar trend is likely to continue during the forecast period. Within that segment residential and “Do-it-yourself” applications are expanding strongly, driving demand for compact, and easy-to-handle products with robust performance. For manufacturers, this creates challenges in designing ergonomic, lightweight and easy-to-handle power tool products.

Currently, drilling, fastening and screwdriving tools hold the largest market share in the power tools market, and a similar trend is likely to continue during the forecast period. Within that segment residential and “Do-it-yourself” applications are expanding strongly, driving demand for compact, and easy-to-handle products with robust performance. For manufacturers, this creates challenges in designing ergonomic, lightweight and easy-to-handle power tool products. A leading power tool manufacturer needed an extremely compact

A leading power tool manufacturer needed an extremely compact

A leading manufacturer in charging infrastructure approached ZETTLER Magnetics in need of a

A leading manufacturer in charging infrastructure approached ZETTLER Magnetics in need of a  When designing electrical equipment for international markets, engineers are forced to consider the requirements of a seemingly growing number of countries. If equipment is connected to the electrical grid, this includes additional safety requirements to isolate and protect people and property from dangerous voltage levels.

When designing electrical equipment for international markets, engineers are forced to consider the requirements of a seemingly growing number of countries. If equipment is connected to the electrical grid, this includes additional safety requirements to isolate and protect people and property from dangerous voltage levels. The

The

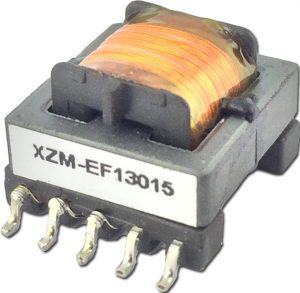

A team of Zettler Magnetics engineers custom-designed a transformer by performing double-layer shielding of the inner and outer layers, while using minimalist skeleton design.

A team of Zettler Magnetics engineers custom-designed a transformer by performing double-layer shielding of the inner and outer layers, while using minimalist skeleton design.

The Design

The Design